Soundtube

Acoustics by channels

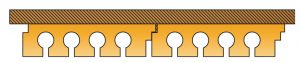

Soundtube® panels are used in offices, apartment buildings, sports centres and shopping centres. The panels consist of channel chip panel made of pure European softwood. The open structure of the wood chips in combination with the channels absorbs the sound energy and shortens the reverberation time.

Six different models.

The channel chip panel is made of engineered solid wood (ESW) in the thickness of 24 or 31 mm. At ESW pretty much all of the tree is used and the material is fully recyclable. The panels meet the D-s3-d0 standard for fire safety and the E1 standard for emissions.

During the production process the top layer is applied on the visible side. Then the channels are grooved open with machines for the following four models:

- model GR 24/2: Groove 4 mm with a c/c distance of approx. 19 mm

- model GR 24/4: Groove 4 mm with a c/c distance of approx. 38 mm

- model GR 31/1: Groove 4 mm with a c/c distance of approx. 25 mm

- model GR 31/2: Groove 4 mm with a c/c of approx. 50 mm

- customer-specific: on request the channels are grooved open in an alternating way

In Soundtube® type GR sound absorption is achieved by the inclusion of sound energy in the channels. In the type of Sound tube® OR extra absorption is achieved by the panels to the opposite side with a slot pattern, whereby the sound energy is also absorbed through the panels by the sound absorbing plenum.

The panels have a fixed width of 607 mm. The standard length is 2500 x 3050 mm

Easy to assemble

The panels are supplied ready mounted and may only be mounted in a conditioned space to prevent excessive expansion and contraction. Subsequently the panels are mounted on a wooden frame, consisting of planed or plywood slats. The panels are glued to the substructure, where a Bush seam of at least 4 mm between the panels in the length direction remains visible. This butt seam is required for expansion of the wood. The panels are invisibly connected in width direction thanks to the handy “lap-over-lap” connection.